Aluminium extrusion

Aluminium extrusion

During aluminium extrusion, you need to protect the plunger by lubricating the billet and the plunger at every extrusion cycle. This operation must be carried out using inert products that do not create residues and ensure excellent release of the aluminium from the plunger.

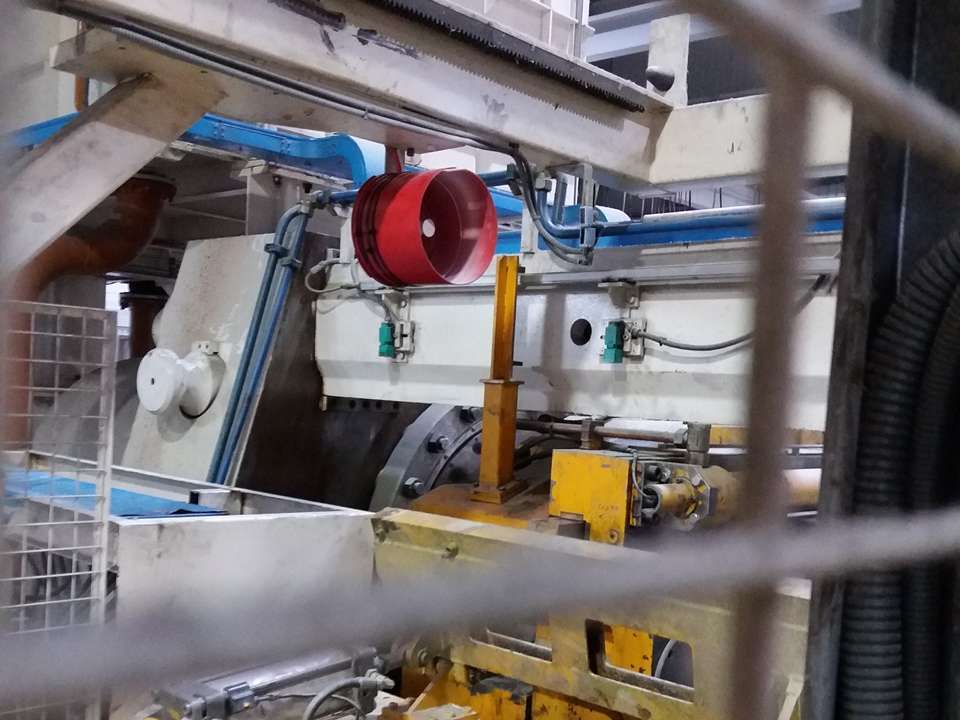

After extensive analyses on the methods currently used, we came up with the DRY LUB SYSTEM, which is exclusively intended for aluminium extrusion. During the design stage, we have worked to manufacture a system that can be easily installed to lubricate the billet and the plunger, paying special attention to the powder supply system, lubrication head, electrostatic generator, environmental dispersion, production costs, and low consumption.

Strengths

Strengths

How the DRY LUB SYSTEM works

The Dry Lub System can be used to lubricate the plunger and the billet. The high electrostatic efficiency, the micro-dosing of the powder, and the simple yet effective shielding system of the dispenser head, allow for excellent adhesion of the powder. The Dry Lub System eliminates waste and dispersions into the environment. Moreover, it improves quality, without leaving residues from the extrusion process.

Any doubts?

Check out our FAQ section. Contact us if you don’t find the answer you were looking for.

No, it doesn’t! We recommend blowing the pipes every 15 to 20 days.

Yes, it’s really easy! It is normally positioned in a fixed place and provides the powder upon the passage of the billet. The lubrication of the plunger is a bit more complicated, as you need to install a moving part.

Our patented injection system prevents irregular puffs, whether they are at the beginning or during the process.

It depends, but always within tenths of seconds.

The product we have designed does not leave any traces or thickness on the plunger.

Our patented system electrostatically supplies a small amount of powder to the billet.

Follow us on